Lesson No. 3:

Reclamation of Abandoned Mine Land by

Re-Mining

Background Information in Preparation for Arbor Day 2011

This lesson plan is provided to assist students participating in the Arbor Day planting event understand the various steps involved in the mining and reclamation process.

Kopper Glo Fuel, Inc. will host the Arbor Day 2011 event at its Tackett Creek Surface Mine #2 in Claiborne County, Tennessee. Students at Clairfield and White Oak Elementary Schools will establish indoor American chestnut nurseries in their classrooms in early 2011 and then transplant them at the planting event in April. In addition to their potted American chestnut seedlings, students will also be planting bare-root seedlings of various species provided by Kopper Glo Fuel and the Tennessee Mining Association.

Example of exposed highwall from pre-SMCRA

mining at site of Tackett Creek Surface Mine #2

prior to re-mining by Kopper Glo Fuel

Four coal seams are being re-mined at the site as follows:

| Coal Creek seam, which averages 34 inches thick | |

| Coal Creek Rider seam, which averages 14 inches thick | |

| Blue Gem seam, which average 32 inches thick | |

| Blue Gem Rider seam, which averages 13 inches thick |

Whereas pre-SMCRA mining was done with little regard to the environment, modern mining is done with protection of the environment as an integral part of the process. Long before the start of mining, water and overburden sampling is performed to provide data for design of the mining plan. A sequence of activities is developed to control runoff and sediment throughout the mining and reclamation process after consultation with the U.S. Army Corps of Engineers, U.S. Fish and Wildlife, U.S. Natural Resources Conservation Service, Tennessee Wildlife Resources Agency, Tennessee Division of Natural Heritage, and Tennessee Historical Commission. These plans must be reviewed and approved by the U.S. Army Corps of Engineers, the U.S. Office of Surface Mining (OSM), and the Tennessee Department of Environment and Conservation (TDEC). At the Tackett Creek Surface Mine #2, planning and preparation of a mine permit application is performed by Mark V Mining and Engineering, Inc., working as a consultant to Kopper Glo Fuel.

Re-mining at the site is done by both surface mining and highwall (auger) mining where coal is removed from beneath an exposed highwall without disturbing the land above it. Highwall mining can rarely be performed beneath a pre-SMCRA highwall due to safety concerns and space limitations. A rockfall from a ragged, pre-SMCRA highwall could damage highwall mining equipment and injure operators; thus, a second cut is required to expose a fresh, unweathered highwall prior to coal removal by highwall mining in accordance with safety standards of the U.S. Mine Safety and Health Administration. Also, highwall mining equipment typically requires a minimum 100-foot wide bench from which to operate.

The sequence of re-mining and reclamation is illustrated in the following photographs and cross-sections for the Blue Gem and Blue Gem Rider seams. A similar sequence is also applicable for mining of the Coal Creek and Coal Creek Rider seams located approximately 350 feet in elevation below the Blue Gem seam.

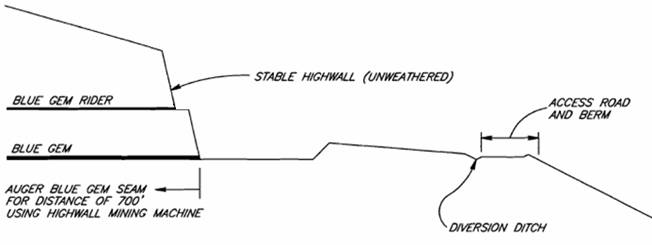

Step 1. Cross-sectional view of conditions prior to re-mining showing

proposed access

road, drainage control, and excavation to create a stable highwall and

recover coal in the

Blue Gem Rider and Blue Gem seams.

Ditches route runoff to sediment basins for runoff

and erosion control. Water quality is monitored

to verify compliance with permitting standards.

After blasting, overburden above the coal is removed

and trucked to backfill adjacent areas of the mine.

Coal is removed and loaded into trucks for transport to a crusher. After

crushing, the

surface-mined coal is loaded directly on railroad cars for transport to the

customer.

Step 2. Cross-sectional view of conditions after a stable highwall and

bench are created by

surface mining. A highwall mining machine is then used to auger coal

from the Blue Gem seam

for a distance of up to 700 linear feet from the face of the stable highwall.

Cut-away view showing how a highwall mining machine removes coal from the

base of the stable

highwall for a distance of 700 linear feet into the mountain. A conveyance

system connected to

the cutting head transports the coal to the open face where it can be loaded

onto trucks for

transport to the coal preparation plant. Use of a highwall mining machine

allows underground

mining to be performed remotely (i.e. miners are not required to go

underground).

Ribs of coal will remain un-mined to support the

highwall for safety of equipment and operators.

After impurities (i.e. silt, clay, shale, etc.)

are removed from the highwall-mined coal at

the preparation plant, it is loaded onto railroad

cars for transport to the customer. In most

cases, clean coal is transported to a power

plant where the coal is burned to

generate electricity.

Step 3. Cross-sectional view showing how spoil removed from an adjacent

section of the surface mine

is used to backfill the highwall, and thus eliminate it after re-mining is

done.

Completed backfill and reclamation to eliminate highwall and return

ground to the approximate

original contour that existed prior to pre-SMCRA mining at the Tackett Creek

Surface Mine #2 site.

This location is where one of the sediment basins was built to control

runoff. As appropriate,

stream channels disrupted by the original pre-SMCRA mining are restored.

Elk at Tackett Creek Surface Mine #2

Elk at Tackett Creek Surface Mine #2

Reclaimed surface mine in Tennessee

prepared according to the Forestry Reclamation

Approach after 8 years of tree growth

Pre-SMCRA surface mine site in Tennessee

after 50 years of tree growth in loose, rocky spoil

Kopper Glo Fuel uses the FRA method during reclamation. In 2009, OSM presented an ARRI Reforestation Award to Kopper Glo Fuel for its King Mountain Surface Mine in Claiborne County. Final reclamation of that mine site resulted in over 100,000 native hardwood trees being planted on 220 acres of reclaimed ground.

The planting site for the Arbor Day 2011 event has been prepared according to the Forestry Reclamation Approach and can be accessed by school buses. Approximately half of the site has been backfilled to a gentle grade, with the remaining outslopes at a steeper grade above a sedimentation basin.

Site for planting of seedlings during

2011 Arbor Day event

<-------

Our goal in the near

future is to establish orchards of blight-resistant hybrids on

mined land in Tennessee as has been done in Ohio

Abandoned mine land in Ohio prior to

re-mining and reclamation according to

the

Forestry Reclamation Approach.

After re-mining and reclamation of

this site

in

Ohio according

to the FRA method, 5,000

blight-resistant hybrid

American chestnut

seedlings were planted in 2008

as part

of a research project with the American

Chestnut Foundation and Ohio University.

Here, the blight-resistant hybrids have everything

they need to grow: sunlight, nutrients, and water.

Prior

to the blight of the early 20th century, the American chestnut

Prior

to the blight of the early 20th century, the American chestnut

was the predominant tree in Appalachia. More details about the

efforts to help blight-resistant hybrids reclaim its former crown as

king of the Appalachian forest can be found at

http://www.charliechestnut.org/